Technology

It is continues to research on high-quality,eco-friendly vertical injection molding machines specialized in insert injection.

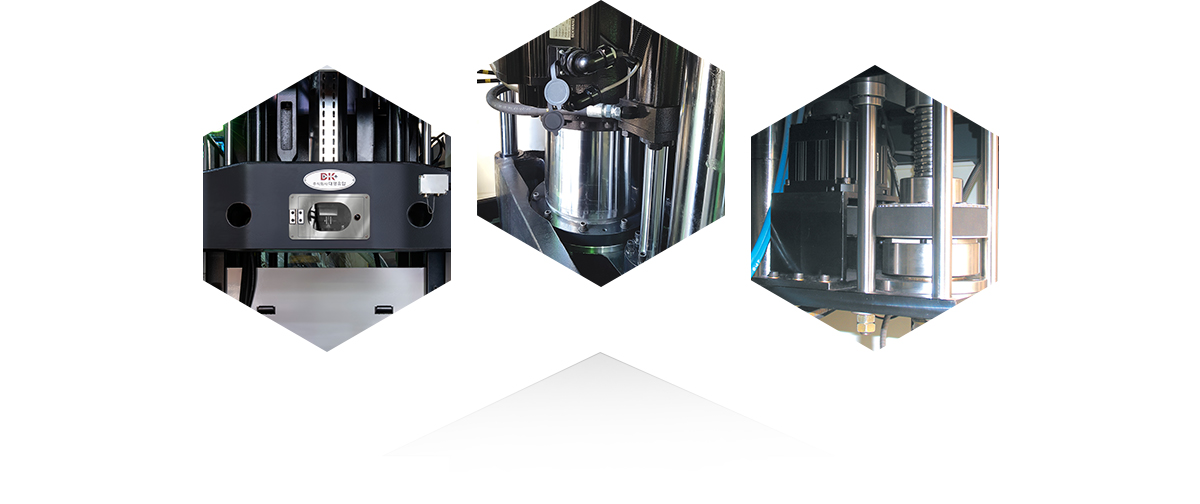

Features of vertical injection molding machine

- Injection Units

-

- By the design of the high-speed injection units, it shows the excellent performance in the precise molding of resin that are extremely difficult to be dealt with.

- With the design of a form of guide bar slide, the degree of precision is excellent and transfer resistance is minimized so that the high speed molding is possible and the reproducibility may be enhanced.

- With anti-corrosive, anti-abrasive bi-metal screw cylinders mounted, molding is safe and the lifespan of screws is greatly increased.

- The adoption of various kinds of injectors : with the application of the designs considering the modulation of an injecting unit in the upper and lower part, it can meet the various requirements and needs of customers and can cope with the diversified molding of all kinds of resins.

- Clamping Units

-

- With the application of design of highly rigid, casting template, durability is enhanced.

- With the adoption of break circuits and stop-bar unit in a rotary table, shock is prevented, and the stability of a mold is secured thanks to the locks and the smooth and precise position control. Since the precise position transducer can detect the movement of clamping cylinder, maintain the position accuracy of a mold, and has a function of high intensity, low-pressure protection, the life cycle of a mold is to be extended.

- With a configuration of various kinds of clamping units, the options for users are expanded, which range from single type, rotary table type, forward and backward moving slide type to leftward and rightward moving slide type.

- By adopting AC servo motor rotation speed control system and high-power electric servo motor driving method, process time is shortened by combined operation (simultaneous operation) that performs product take-out and inserts inserting process during mold closing and injection process.

Vertical injection molding machines are specialized for insert injection,

which has a risk of mold accident and difficult to insert work

with horizontal injection molding machine.